TerraNova Energy

Technology

Technology HTC

Hydrothermal Carbonization

Technology THP

Thermal Hydrolysis Process

Technology Phosphorous recovery

Technology Nitrogen-removal and -recovery

Outlook to the future

Technology HTC

The TerraNova®ultra process mimics and significantly accelerates the process of natural coal formation – it is based on the process of Hydrothermal Carbonization (HTC):

After downstream dewatering, the HTC coal contains hardly any water and, thanks to its high energy content, can be used for climate-friendly energy generation in coal-fired power plants or as a substitute for fossil fuels in cement plants or waste incineration plants.

As a further product, the HTC delivers the water extracted from the bio waste. This HTC filtrate is low in pollutants, sterilized and rich in nutrients.

HTC coal from sewage sludge with 65% dry matter content

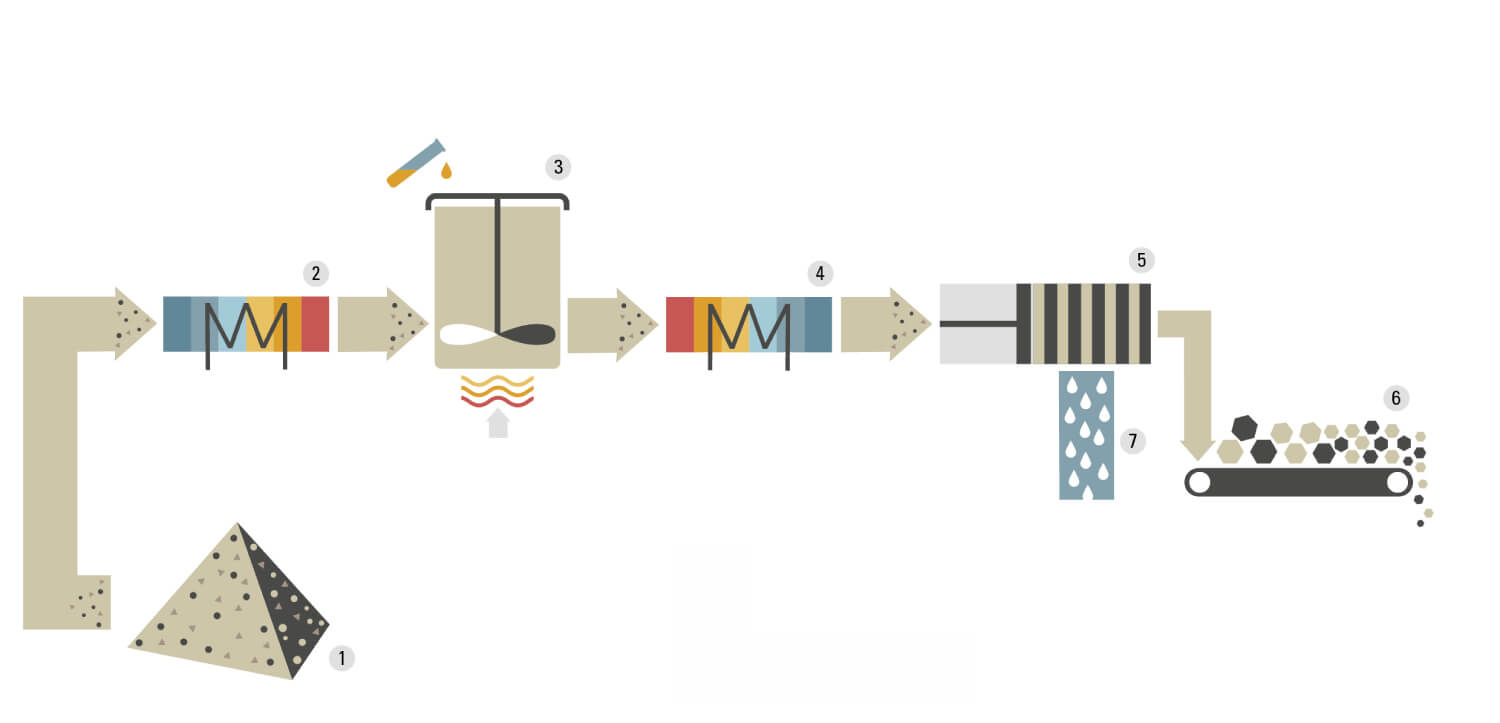

Dewatered sewage sludge or shredded biowaste (1) with a dry matter content of 5-30% is fed into the input heat exchanger (2) by means of a high-pressure pump.

The preheated biomass is carbonized in a stirred reactor (3) with addition of catalysts at up to approx. 200°C for about 5 hours. The stirred reactor is jacket-heated by a thermal oil circuit. The heat source can be, for example, the exhaust gas heat of a combined heat and power plant.

The resulting carbon slurry is cooled via the output heat exchanger (4). The heat energy extracted in the process is fed back to the input heat exchanger (2) via a separate thermal oil circuit.

In a dewatering unit, for example a fully automated chamber filter press, the coal is dewatered to a dry substance content of 65-70% (5).

The TerraNova® HTC coal (6) is automatically removed from the press and can optionally be dried in a downstream low-temperature, exhaust air free drying unit.

The HTC filtrate (7) separated during dewatering can be utilized for the recovery of phosphorus, nitrogen or biogas in subsequent treatment stages.

Hydrolyzed sewage sludge with 22% dry matter

Technology THP

During the thermal hydrolysis process THP, the organic structure of the feedstock is broken down by the effect of temperature and pressure in order to make it more usable in downstream biological processes. It is commonly used to increase the digester gas yield of biogas processes.

TerraNova®lysis performs a novel, intensive thermal pressure hydrolysis of the feedstock. In this process, the material is pre-treated at temperatures of 160-170°C for a particularly long period of several hours to enable more effective anaerobic conversion to biogas by the bacteria in the subsequent digestion process. In this way, for example, an increase in biomethane potential (BMP) of approx. 35% is achieved for sewage sludge (mixture of primary sludge and activated sludge) – a much higher value than with conventional processes with shorter effective times. If solely the comparatively poorly useable activated sludge is treated, the effect is even greater.

In addition to the long treatment time, the special feature of TerraNova®lysis is its ability to process even material with a very high dry substance content of up to 30%. This makes small, compact plants possible. The energy consumption of the process is very low due to the integrated heat recovery, the high concentration of the material to be treated and the absence of steam as a heat transfer medium, amounting to only 110 kWh of heat and 16 kWh of electrical energy per ton of input.

TerraNova®lysis also improves the dewatering ability of the fermentation residues and thus helps to minimize residual materials.

Technology THP

Hydrolyzed sewage sludge with 22% dry matter

During the thermal hydrolysis process THP, the organic structure of the feedstock is broken down by the effect of temperature and pressure in order to make it more usable in downstream biological processes. It is commonly used to increase the digester gas yield of biogas processes.

TerraNova®lysis performs a novel, intensive thermal pressure hydrolysis of the feedstock. In this process, the material is pre-treated at temperatures of 160-170°C for a particularly long period of several hours to enable more effective anaerobic conversion to biogas by the bacteria in the subsequent digestion process. In this way, for example, an increase in biomethane potential (BMP) of approx. 35% is achieved for sewage sludge (mixture of primary sludge and activated sludge) – a much higher value than with conventional processes with shorter effective times. If solely the comparatively poorly useable activated sludge is treated, the effect is even greater.

In addition to the long treatment time, the special feature of TerraNova®lysis is its ability to process even material with a very high dry substance content of up to 30%. This makes small, compact plants possible. The energy consumption of the process is very low due to the integrated heat recovery, the high concentration of the material to be treated and the absence of steam as a heat transfer medium, amounting to only 110 kWh of heat and 16 kWh of electrical energy per ton of input.

TerraNova®lysis also improves the dewatering ability of the fermentation residues and thus helps to minimize residual materials.

Phosphorus recovery technology

In the TerraNova® process, phosphorus can be recovered from sewage sludge, liquid manure or other biomass without prior incineration – in a decentralized plants and with the highest recovery efficiency compared to other processes.

Phosphorus recovery can be added to existing TerraNova® plants as an option: After treatment of the bio waste in the TerraNova® process, a liquid coal slurry is formed, to which acid is added for phosphorus recovery. By lowering the pH value, the contained phosphorus is dissolved into the liquid phase – this is also referred to as phosphorus leaching. The phosphorus-rich liquid is then separated from the solids in a mechanical press.

This separation takes place with a very high efficiency, since hardly any phosphorus-containing liquid remains in the remaining filter cake with a dry matter content of about 70%. In addition, the humic and carbon structures in the filter cake retain a large proportion of the heavy metals, making the recovered phosphorus particularly low in pollutants.

TerraNova Energy – Phosphorus Recovery Technology

CSH (calcium silicate hydrate) granules are then added to the phosphorus-rich liquid, to which the phosphorus adsorbs to form amorphous phosphorus compounds, hydroxyapatite and struvite.

The resulting phosphorus product complies with the current German and European Fertilizer Ordinance and has demonstrated excellent fertilizer efficiency in independent tests.

The patented TerraNova® process for phosphorus recovery can be applied to all types of sewage sludge (raw sludge, digested sludge, iron, aluminum precipitated sludge or biological P-removal) and, depending on the amount of acid used for leaching, achieves recovery rates of 60-70% from dewatered sewage sludge.

Nitrogen separation and recovery technology

Next to carbon, nitrogen is the most important component of biowaste and sewage sludge. And it is both a curse and a blessing: In biological conversion processes or during incineration, nitrogen oxides NOx and nitrous oxide N2O are produced, gases that are harmful to the climate and to health. During intense fertilization, it enters groundwater as the potentially toxic nitrate NO3 or causes the eutrophication of open waters as ammonium NH4.

At the same time, nitrogen is the most important fertilizer for securing our food production. Thus, more than 40% of the world’s population could not be fed without industrially produced ammonia. However, the Haber-Bosch process used for this purpose is very energy-intensive and is responsible for about 3% of the world’s energy needs. Rising energy prices, caused by global efforts to combat climate change, thus have a direct impact on the production costs of nitrogen fertilizers and thus on food prices.

Next to carbon, nitrogen is the most important component of biowaste and sewage sludge. And it is both a curse and a blessing: In biological conversion processes or during incineration, nitrogen oxides NOx and nitrous oxide N2O are produced, gases that are harmful to the climate and to health. During intense fertilization, it enters groundwater as the potentially toxic nitrate NO3 or causes the eutrophication of open waters as ammonium NH4.

At the same time, nitrogen is the most important fertilizer for securing our food production. Thus, more than 40% of the world’s population could not be fed without industrially produced ammonia. However, the Haber-Bosch process used for this purpose is very energy-intensive and is responsible for about 3% of the world’s energy needs. Rising energy prices, caused by global efforts to combat climate change, thus have a direct impact on the production costs of nitrogen fertilizers and thus on food prices.

The TerraNova® process offers different solutions depending on the application:

Outlook to the future

TerraNova Energy utilizes hydrothermal carbonization (HTC) as a platform technology. Our worldwide network of research institutes, however, is also constantly working on future topics that promise exciting new applications for HTC:

Outlook to the future

TerraNova Energy utilizes hydrothermal carbonization (HTC) as a platform technology. Our worldwide network of research institutes, however, is also constantly working on future topics that promise exciting new applications for HTC:

CO2 capture and storage (CCS) in the soil to achieve negative emissions.1

Avoidance of climate gas emissions, especially nitrous oxide, in the use of organic fertilizers.2

Replacement of fossil coke as a reducing agent for steel production.3

Climate-friendly nitrogen production to avoid the energy-intensive Haber- Bosch process.3

Regenerative activated carbon for adsorption of gas (CO2, H2, CH4, H2S), pollutants (wastewater) and heavy metals.3

Carbon-based electrode materials for batteries and supercapacitors.3

Regenerative sacrificial electrode in hydrogen electrolysis.3

Production of 5-HMF as a bio-based feedstock for the chemical industry.3

Synthesis of carbon dots, microscale structures e.g. for optoelectronic applications.4

1 researchgate.net 269261607

1 researchgate.net 357885937

2 mdpi.com

3 https://pubs.rsc.org/en/content/articlelanding/2020/gc/d0gc00998a#!

4 Recent advances in hydrothermal carbonisation:

from tailored carbon materials and biochemicals to applications and bioenergy, Nicolae et al, Green Chem, 2020, 22, 4747